Go digital

with SYNKRO

Go digital

with SYNKRO

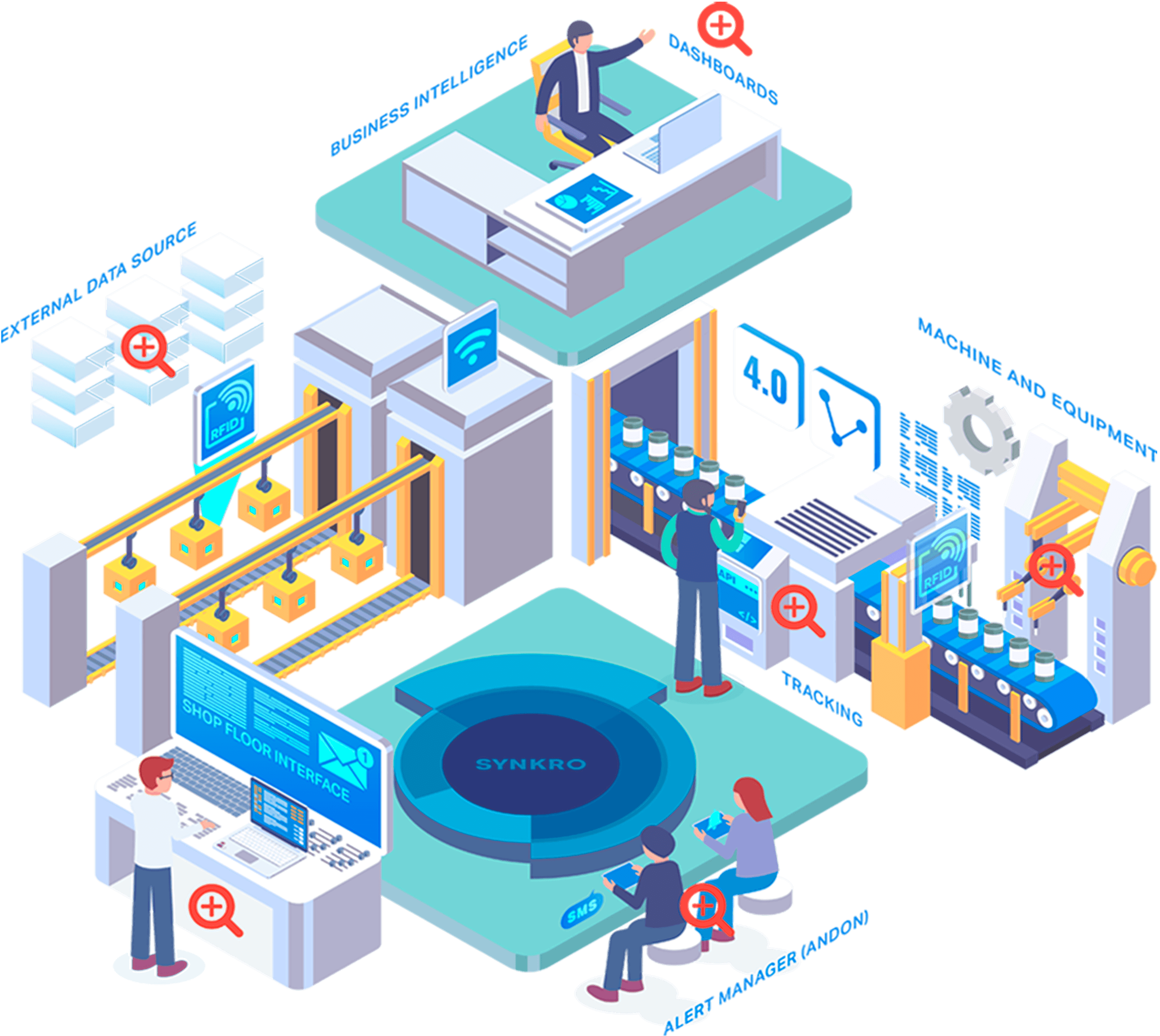

What SYNKRO does

Collects, processes, and distributes all your production event data in real time

Allows you to view your performance indicators and data in real time

Compares your ‘planned’ with your ‘actual’ to enable you to make the right decisions at the right time

Versatile functionalities to suit your plant's needs

Synkro – EN

Dashboards and business intelligence

We bring together all the operational data you need in a clear, easy-to-use format so you can run your processes without any superfluous information. Get access to the information you need in real time and easily configure your indicators based on current issues to make decisions fast. Whether you want to use Power BI, Tables, or any other data visualization tool, our team will help you make your data speak for itself!

Dashboards and business intelligence

We bring together all the operational data you need in a clear, easy-to-use format so you can run your processes without any superfluous information. Get access to the information you need in real time and easily configure your indicators based on current issues to make decisions fast. Whether you want to use Power BI, Tables, or any other data visualization tool, our team will help you make your data speak for itself!

External data source

Connect your plant and software to your business processes and view your collected data in real-time. Collect your data at the source, make it available for analysis and view it in the tool of your choice. Our ETL (Extract Transfer Load) system is specifically designed to offer performance and flexibility when interfacing with different information technologies. Whether you need to collect information from an ERP, MES, or a traditional file like Excel, our ETL is perfect for integrating and structuring this data in Synkro.

Floor entry interface

No more paper entries! With the personalized interfaces offered to operators, they can enter information related to their operation in real-time and get instant feedback. These interfaces are ideal for entering your work stoppages (machine or operational) and for sending orders to others on the floor (dispatcher). Some MES functionality will also be available soon.

Alert management (ANDON)

Facilitate the coordination between your maintenance and supervision teams with our Alert Management System (ANDON). Our alert management system will allow you to accelerate the decision-making on your production floor by alerting either by Microsoft Teams, SMS, or email the right resources and directing them to the right intervention site.

Traceability

The traceability function allows you to locate your human resources, work orders, raw materials, and finished products in your plant. In addition to detecting your operational activities, our team will guide you towards the most suitable technology (RFID or BLE – Bluetooth Low Energy) according to your needs for tracking your resources.

Machines and equipment

Connect your plant and equipment to your business processes and visualize your data in real-time. No matter what type of equipment you have, whether it be a CNC machine or automated or semi-automated equipment, we will use the native capabilities or integrate our intelligent acquisition systems. We support the most popular protocols such as MTConnect, OPC UA, MQTT, FOCAS2, S7, Heidenhain, REST, Modbus, and more.